Product Description

Sludge Dewatering Machine

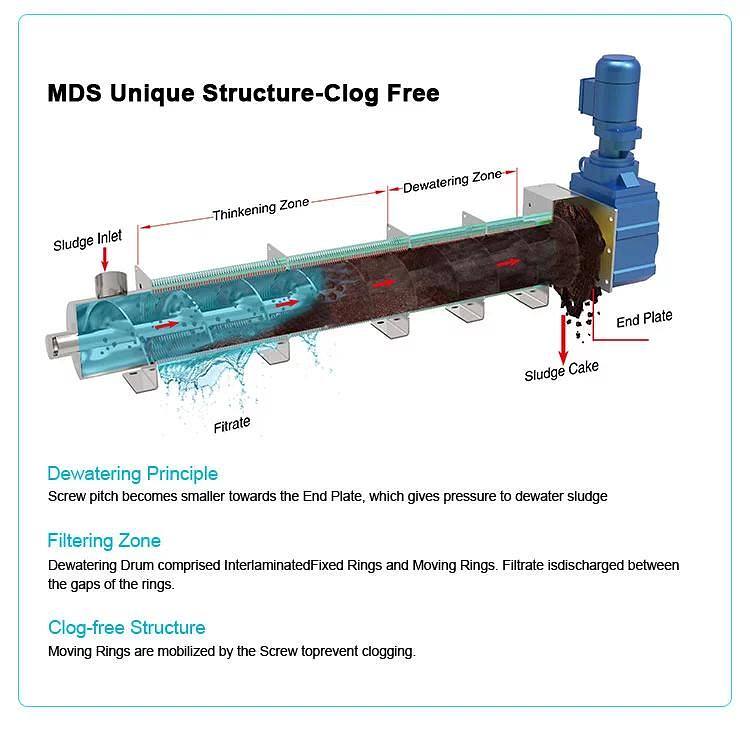

The initial section of dewatering drum is the Thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake.

MDS Model Selection

|

Model |

WAS Sludge & Chemical Precipitated Sludge (Thin Sludge) |

Dissolved Air Flotation Sludge |

Mixed Raw Sludge Aerobic Digested Sludge & Sewage Sludge |

||

|

Sludge Concentration (TS) |

0.2% |

1% |

2% |

5% |

3% |

|

BC-MDS 051 |

~0.4 kg-DS/hr |

~0.6 kg-DS/hr (0.06 m³/hr) |

~2 kg-DS/hr (0.1 m³/hr) |

~4 kg-DS/hr |

~5 kg-DS/hr |

|

BC-MDS 101 |

~2 kg-DS/hr |

~3 kg-DS/hr |

~5 kg-DS/hr |

~10 kg-DS/hr |

~13 kg-DS/hr |

|

BC-MDS 131 |

~4 kg-DS/hr |

~6 kg-DS/hr |

~10 kg-DS/hr |

~20 kg-DS/hr |

~26 kg-DS/hr |

|

BC-MDS 132 |

~8 kg-DS/hr |

~12 kg-DS/hr |

~20 kg-DS/hr |

~40 kg-DS/hr |

~52 kg-DS/hr |

|

BC-MDS 202 |

~16 kg-DS/hr |

~24 kg-DS/hr |

~40 kg-DS/hr |

~80 kg-DS/hr |

~104 kg-DS/hr |

|

BC-MDS 311 |

~20 kg-DS/hr |

~30 kg-DS/hr |

~50 kg-DS/hr |

~100 kg-DS/hr |

~130 kg-DS/hr |

|

BC-MDS 312 |

~40 kg-DS/hr |

~60 kg-DS/hr |

~100 kg-DS/hr |

~200 kg-DS/hr |

~260 kg-DS/hr |

|

BC-MDS 313 |

~60 kg-DS/hr |

~90 kg-DS/hr |

~150 kg-DS/hr |

~300 kg-DS/hr |

~390 kg-DS/hr |

|

BC-MDS 412 |

~80 kg-DS/hr |

~120 kg-DS/hr |

~200 kg-DS/hr |

~400 kg-DS/hr |

~520 kg-DS/hr |

|

BC-MDS 413 |

~120 kg-DS/hr |

~180 kg-DS/hr |

~300 kg-DS/hr |

~600 kg-DS/hr |

~780 kg-DS/hr |

Main Features

1)Japan original technology, Japan quality control.

2) Direct dewatering thin sludge from Oxidation Ditch.

3) Wide variety of sizes, widely applications.

4) Low running cost, 24-hour automated operation.

5) Easy operation & maintenance, long service life (≥15 years).

6) Clog-free design, suitable for oily sludge.

7) Small footprint, smart design.

MDS Specifications

|

Model |

Cylinder Specifications/mm |

Sludge Cake Outlet Distance/mm |

Machine Specifications/mm |

Net Weight KG |

Running Weight KG |

Power KW |

Rinsing Water L/h |

||

|

Length |

Width |

Height |

|||||||

|

BC-MDS 051 |

Ø50*1 |

215 |

1105 |

656 |

980 |

100 |

120 |

0.2 |

12 |

|

BC-MDS 101 |

Ø100*1 |

215 |

1816 |

756 |

1040 |

200 |

290 |

0.2 |

24 |

|

BC-MDS 131 |

Ø130*1 |

250 |

1969 |

756 |

1040 |

220 |

315 |

0.2 |

24 |

|

BC-MDS 132 |

Ø130*2 |

250 |

2069 |

910 |

1040 |

305 |

450 |

0.3 |

48 |

|

BC-MDS 202 |

Ø200*2 |

350 |

2500 |

935 |

1270 |

520 |

730 |

0.8 |

64 |

|

BC-MDS 311 |

Ø310*1 |

495 |

3255 |

985 |

1600 |

910 |

1320 |

0.8 |

40 |

|

BC-MDS 312 |

Ø310*2 |

495 |

3455 |

1295 |

1600 |

1530 |

2230 |

1.2 |

80 |

|

BC-MDS 313 |

Ø310*3 |

495 |

3605 |

1690 |

1600 |

2090 |

3080 |

1.95 |

120 |

|

BC-MDS 412 |

Ø410*2 |

585 |

4140 |

1550 |

2250 |

2450 |

3400 |

3.75 |

144 |

|

BC-MDS 413 |

Ø410*3 |

585 |

4420 |

2100 |

2250 |

3350 |

4850 |

6.0 |

216 |

Running Conditions

|

Model |

Power /kw |

Rinsing Water Pressure |

Maintenance Frequency |

Vulnerable Part Replacement Cycle /h |

|||

|

Screw |

Mixer |

Total |

Screw shaft |

Moving rings |

|||

|

BC-MDS 051 |

0.1 |

0.1 |

0.2 |

0.1Mpa-0.2Mpa (no need high pressure washing device, tap water is fine) |

5min/day |

1000 |

5000 |

|

BC-MDS 101 |

0.1 |

0.1 |

0.2 |

1000 |

5000 |

||

|

BC-MDS 131 |

0.1 |

0.1 |

0.2 |

1000 |

5000 |

||

|

BC-MDS 132 |

0.2 |

0.1 |

0.3 |

1000 |

5000 |

||

|

BC-MDS 202 |

0.4 |

0.4 |

0.8 |

15000 |

7500 |

||

|

BC-MDS 311 |

0.4 |

0.4 |

0.8 |

30000 |

10000 |

||

|

BC-MDS 312 |

0.8 |

0.4 |

1.2 |

30000 |

10000 |

||

|

BC-MDS 313 |

1.2 |

0.75 |

1.95 |

30000 |

10000 |

||

|

BC-MDS 412 |

3.0 |

0.75 |

3.75 |

30000 |

10000 |

||

|

BC-MDS 413 |

4.5 |

1.5 |

6 |

30000 |

10000 |

||

PRODUCT MESSAGE