Product Description

MBBR Media

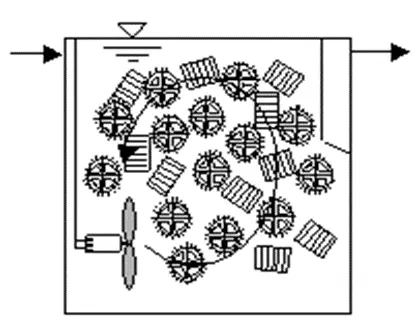

The BioCellTM media are suitable for a moving bed biofilm reactor (MBBR) system to provide a self-shedding, self-regulating growth biofilm treatment process. The media can be used for MBBR treatment alone or as an integrated fixed membrane activated sludge (IFAS) process to enhance the effective capacity of existing activated sludge systems.

The BioCellTM medium used in MBBR or IFAs is a continuous motion caused by air injection and agitator. Specific density of the media can be adjusted between 0.95-1.05 g/cm3 according to customer requirements. However, it should be considered that with the formation of biofilm on the surface of the medium, the actual density of the carrying media will increase.

|

|

|

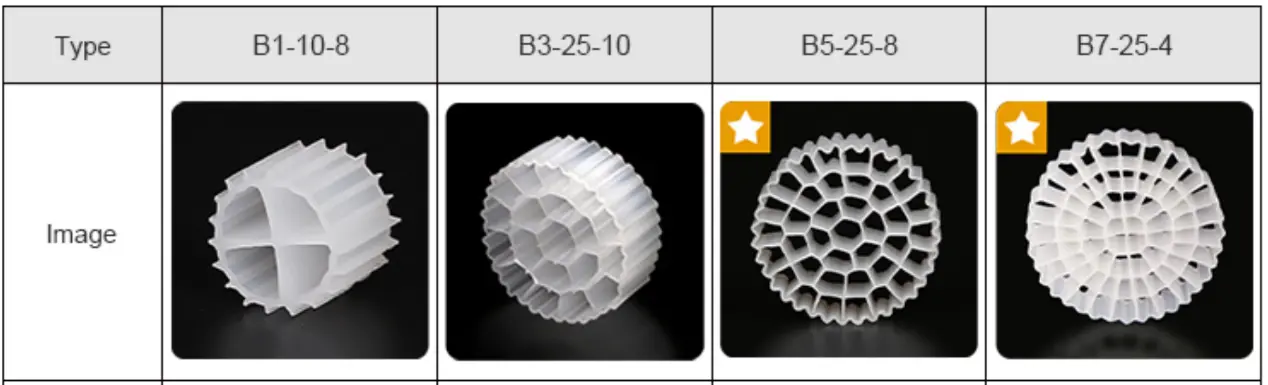

Model |

B1-10-8 |

B2-16-10 |

B3-25-10 |

B5-25-8 |

B7-25-4 |

|

Dimension(mm) |

Ø10×8 |

Ø16×10 |

Ø25×10 |

Ø25×8 |

Ø25×4 |

|

Density(g/cm3) |

0.96± 0.02 |

0.96± 0.02 |

0.96± 0.02 |

0.96± 0.02 |

0.96± 0.02 |

|

Total surface area(m2/m3) |

>1000 |

>1000 |

>620 |

>800 |

>1450 |

|

Protected surface area (m2/m3) |

>800 |

>800 |

>500 |

>650 |

>1200 |

|

Bulk density(pcs/m3) |

> 830,000 |

> 270,000 |

>120,000 |

>118,000 |

>220,000 |

|

Filling rate(%) |

15~55 |

15~55 |

15~65 |

15~65 |

15~65 |

|

Material |

HDPE |

HDPE |

HDPE |

HDPE |

HDPE |

|

Service life |

>15 years |

>15 years |

>15 years |

>15 years |

>15 years |

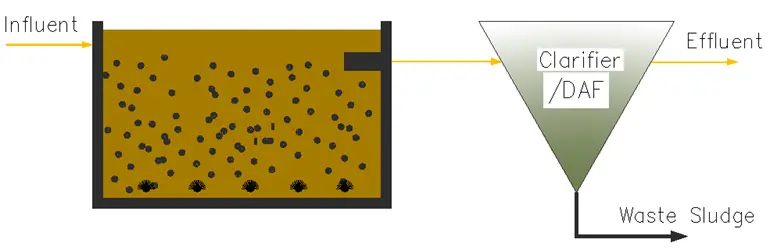

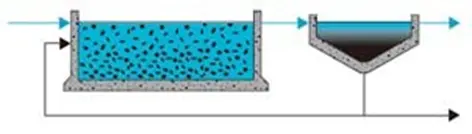

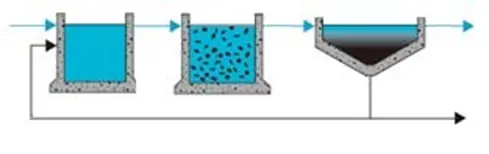

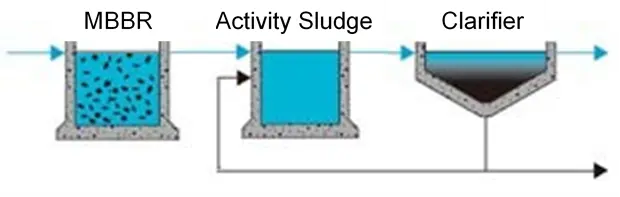

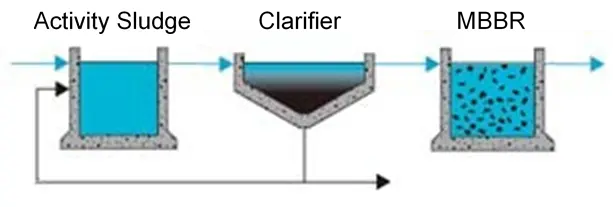

Moving Bed Biofilm Reaction (MBBR)

The main characteristic of Moving Bed Biological Reactor (MBBR) configurations is that there is no sludge recycle from a secondary clarifier. MBBR is essentially a simple, once-through process, where all of the biological activity takes place on the biomass carriers. MBBR is usually followed by a solids separation system such as a secondary clarifier or DAF, in order to separate bio-solids produced in the process from the final effluent. The main advantage of MBBR is robust and simple reduction of soluble pollutants (soluble BOD or COD, NH4 +, etc.), with minimal process complexity, utilizing a significantly smaller footprint when compared to conventional aerobic treatment methods. MBBR is typically used for either high load industrial applications or for robust simple-to-operate municipal facilities.

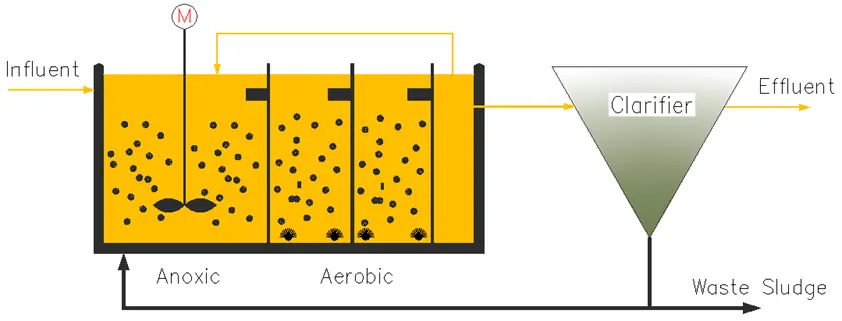

Integrated Fixed-lm Activated Sludge (IFAS )

The Integrated Fixed-film Activated Sludge (IFAS) process combines the advantages of conventional activated sludge with those of biofilm systems by combining the two technologies in a single reactor. Typically, an IFAS configuration will be similar to an activated sludge plant (utilizing all of the different process configurations such as MLE, UCT, Bardenpho, etc.), with biomass carriers introduced into carefully selected zones within the activated sludge process. This allows two distinct biological populations to act synergistically, with the MLSS degrading most of the organic load (BOD), and the biofilm creating a strongly nitrifying population for oxidation of the nitrogenous load (NH4+). IFAS is typically used to upgrade existing plants in order to enable extensive Nitrogen removal, or in designing new plants with significantly smaller footprints for extensive BOD and Nitrogen removal.

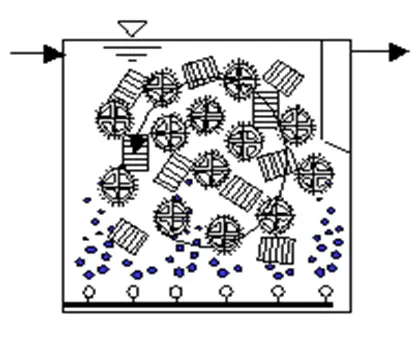

MBBR Process Application

|

|

MBBR Aerobic Reactor

|

|

|

|

PRODUCT MESSAGE